IN SITU MATERIAL EXCHANGE

IN SITU

Material

Exchange

OPEN-FLUIDIC REPLACEMENT OF LIQUID PRINT MATERIAL

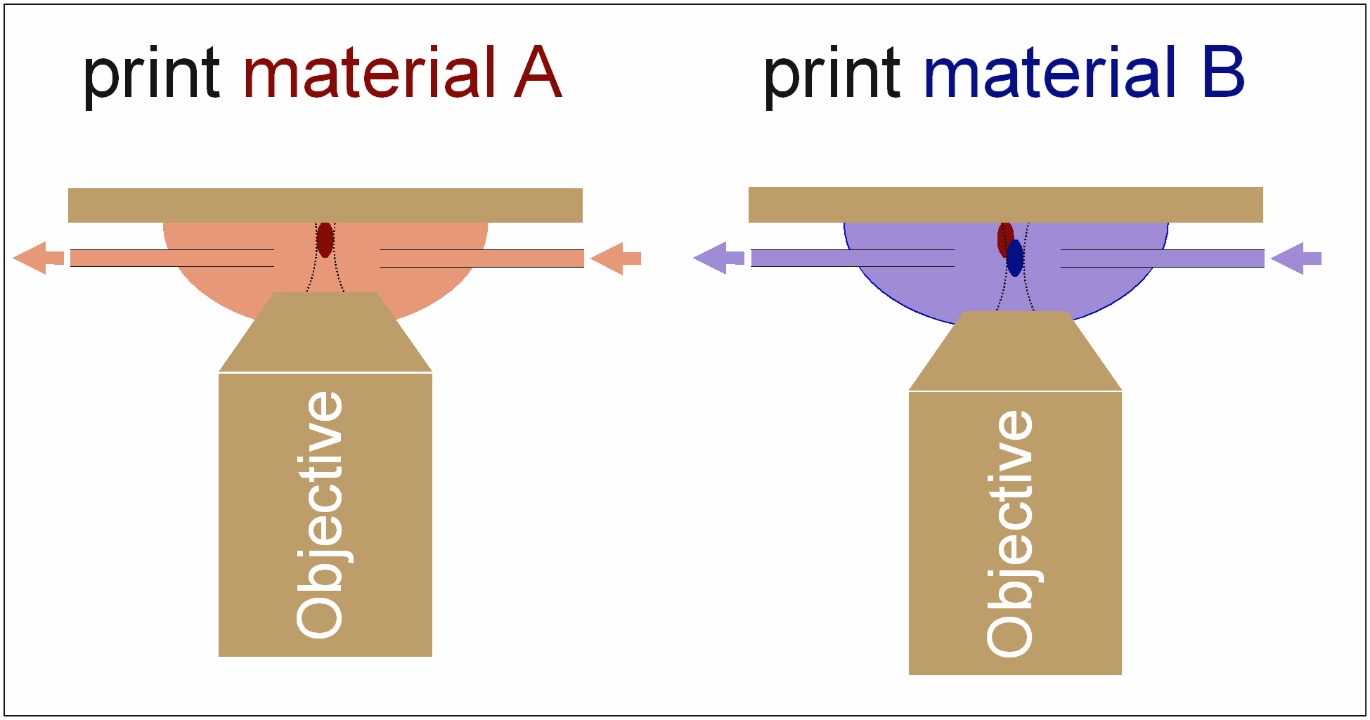

The HETEROMERGE technology utilizes an integrated open-fluidic flow system to exchange liquid printing material in 2-photon polymerization (2PP) based 3D laser printing. The open-fluidic concept allows for complete versatility in print geometry and build volume. Our system is compactly integrated with the liquid-immersed 3D printer optics, ensuring an effective printing material exchange. We incorporate the HETEROMERGE technology into existing 2PP printers.

TECHNOLOGY BACKGROUND

2PP 3D printing

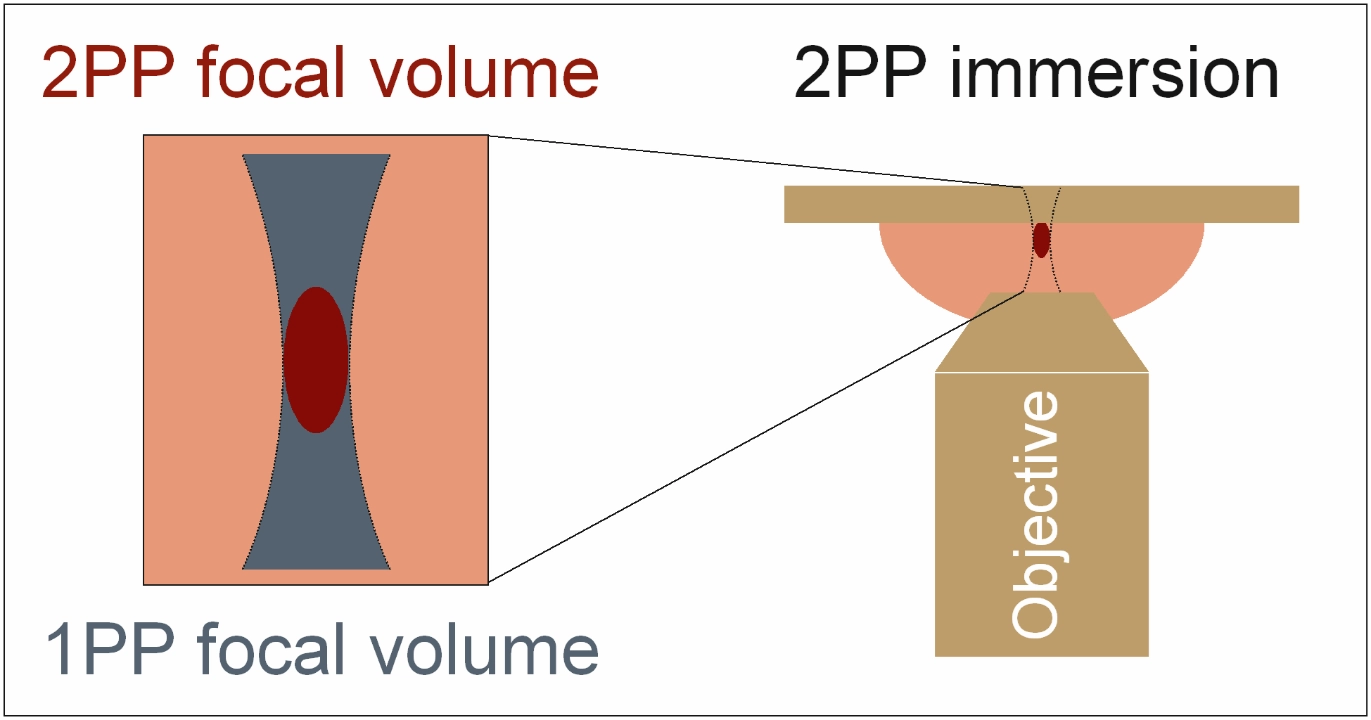

2PP 3D printing is one of the highest-resolving and fastest 3D printing methods. It uses near-infrared (NIR) light to polymerize liquid precursor materials. A non-linear physical effect called 2-photon or multi-photon absorption occurring at very high laser intensities allows for significantly smaller 3D features compared to standard 1-photon polymerization (1PP) based 3D laser printing.

Technological challenge and HETEROMERGE solution

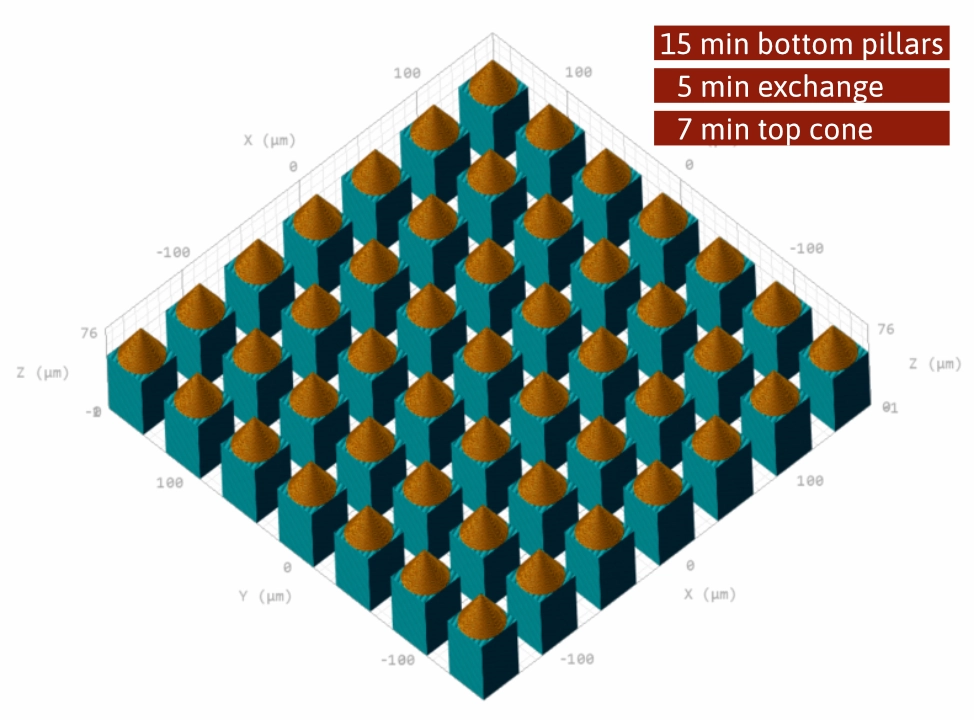

To enable multi-material 2PP printing, the printing material must be changed during the print build-up. We rely on an in situ exchange of the active printing material, while both the laser focus and the substrate to be printed on are held in position. This is one of our core concepts and is key for aligning with pre-existing and pre-printed structures.

HETEROMERGE enabled competitive advantages

The unique combination of the HETEROMERGE open-fluidic system with the existing 2PP 3D printing technology provides clear advantages compared to direct and indirect competitive solutions.

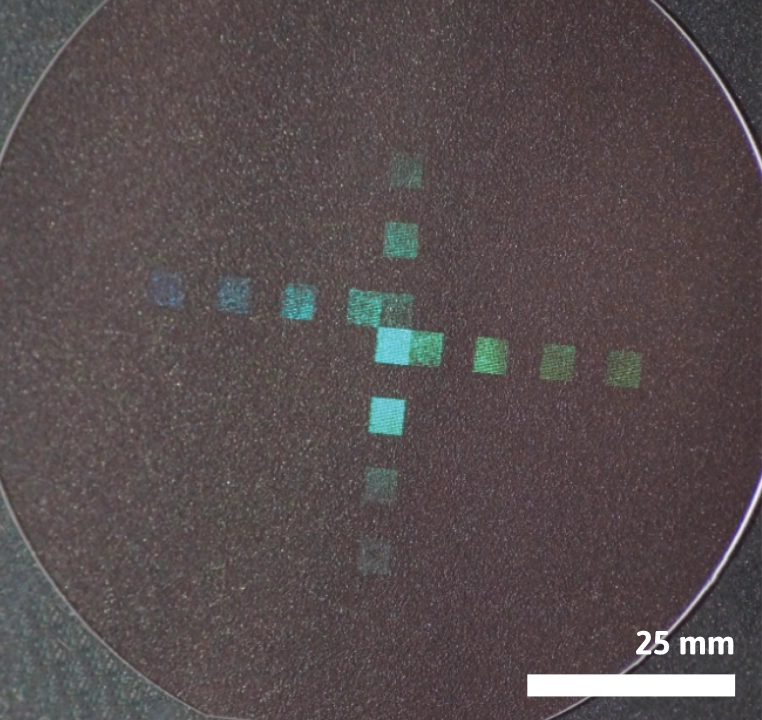

Perfect Alignment

The in situ material exchange during immersion prevents any relative movements of the printer focus and the substrate. This guarantees a lateral overlay accuracy better than 50 nm between two consecutive material sections, basically only limited by the positioning accuracy of the printer. Such an overlay accuracy is up to 100x better than standard solutions.

Fast multi-material prints

The in situ material exchange omits any manual handling steps to change the print material. Our software automates material exchange and printing, minimizing material switchover and overhead times for fast multi-material printing. Our process becomes up to 10x faster than manual material exchange.

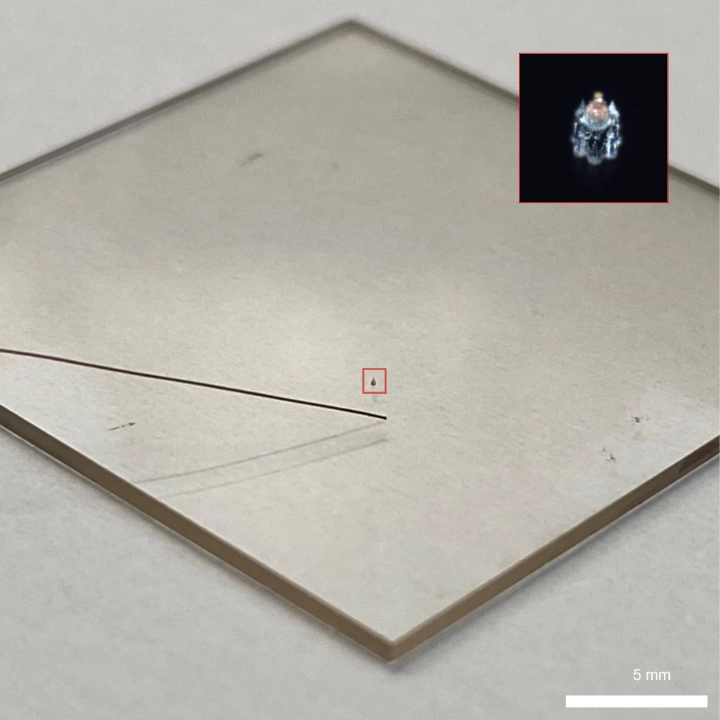

Substrate independence

Due to our open-fluidic concept, our printhead is entirely independent of the substrate chosen for printing. This allows for highly flexible multi-material printing, from small prototypes to large fabrication substrates such as wafers. Our technology can operate on both, transparent and opaque substrates. Printing on existing devices is also possible. Additionally, our technology offers a volume-conserving material supply, which is ideal for large-area printing.

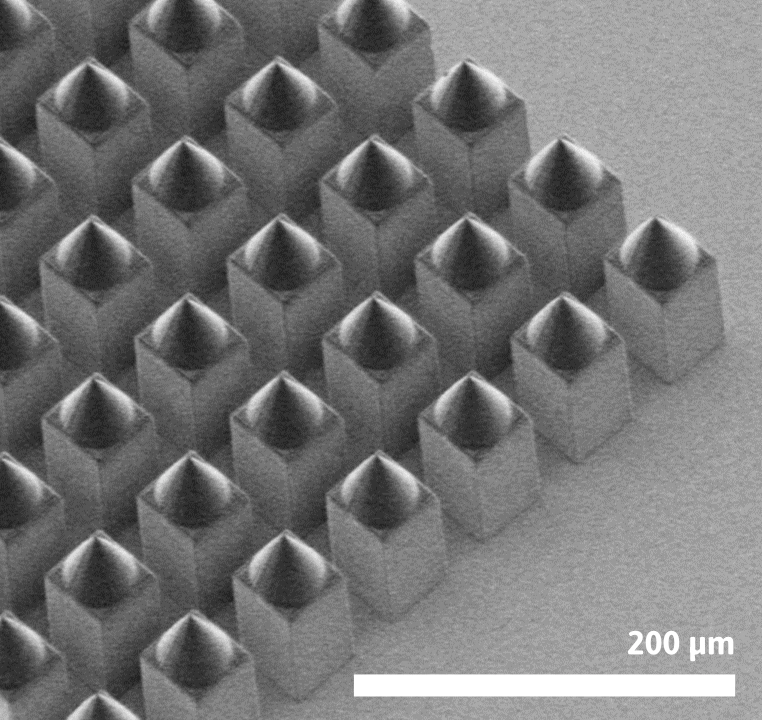

Finest 3D definition

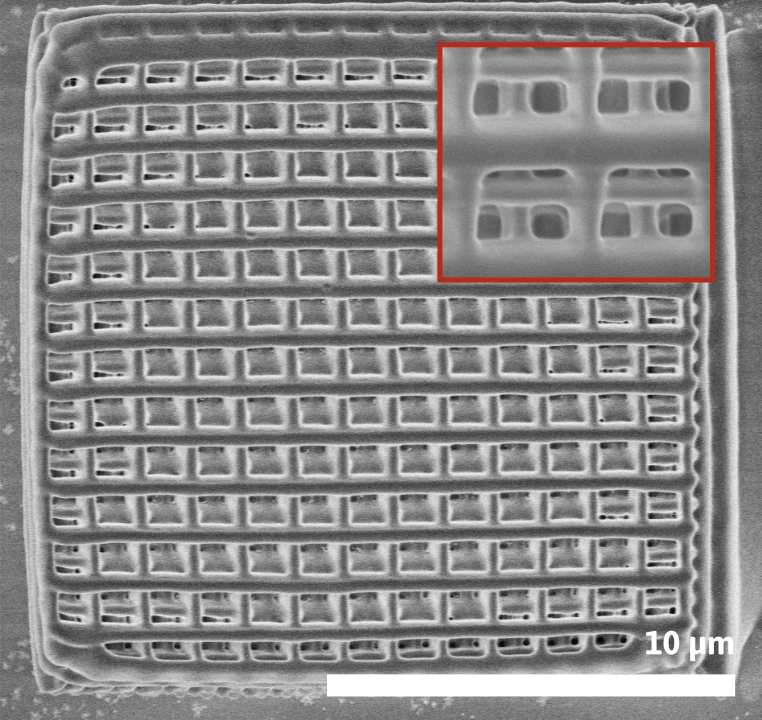

Our printhead does not interfere with the 2PP base technology, and the full 2PP capabilities remain available. Depending on the focusing optics, the base technology can reach down to 150 nm half-pitch resolution (optimized isolated feature size) and about 350 nm pitch resolution (dense feature distance), laterally. Vertically, 400 nm half-pitch and 850 nm pitch resolution are possible.